Embracing Zero Liquid Discharge in Bangladesh in 2024

In the ever-evolving landscape of Bangladesh’s textile industry, a revolution is brewing – one that promises to redefine the nation’s commitment to environmental sustainability. As we stride into 2024, the clarion call for Zero Liquid Discharge (ZLD) echoes louder than ever, resonating across factories and communities alike.

The Pressing Need for Change

Bangladesh’s textile sector, a cornerstone of the country’s economic prowess, has long grappled with the challenges of industrial wastewater treatment. Conventional effluent treatment plants (ETPs) have fallen short, leaving a trail of polluted waterways and jeopardizing public health. With government regulations tightening and global consumers demanding eco-friendly practices, the time has come for a radical transformation.

Embracing ZLD: A Paradigm Shift

Enter Zero Liquid Discharge, a revolutionary approach that promises to eliminate the release of untreated industrial wastewater into the environment. By harnessing cutting-edge technologies and adopting a circular mindset, ZLD enables the recovery and reuse of valuable resources, minimizing waste, and promoting a sustainable textile production model.

Overcoming Obstacles

Transitioning to ZLD is no small feat, with challenges ranging from substantial capital costs to the complexities of sludge management. However, Bangladesh’s textile industry is no stranger to adversity, and its resilience shines through as pioneers blaze the trail.

Small and Medium Enterprises (SMEs) Leading the Charge

While larger corporations may have the resources to invest in state-of-the-art ZLD systems, it is the SMEs that are truly paving the way. Driven by a passion for innovation and a commitment to environmental stewardship, these nimble businesses are exploring cost-effective ZLD solutions tailored to their unique needs.

“We may be small, but our impact is mighty,” says Rafiq Ahmed, owner of a thriving textile SME in Narayanganj. “Adopting ZLD is not just about compliance; it’s about leaving a better world for our children.”

Unlocking Opportunities

Beyond environmental benefits, ZLD presents a multitude of opportunities for Bangladesh’s textile industry:

- Water reuse: With the ability to recycle and reuse treated wastewater, factories can significantly reduce their freshwater consumption, bolstering water security and cost savings.

- Resource recovery: ZLD systems can recover valuable resources like salt, minerals, and even dyes, creating new revenue streams and promoting a circular economy.

- Energy efficiency: Advanced ZLD technologies often incorporate energy-efficient processes, reducing a factory’s carbon footprint and operating costs.

- Competitive edge: As global brands prioritize sustainable supply chains, ZLD-compliant factories gain a significant competitive advantage in the international market.

Government Support: Fueling the Transformation

Recognizing the pivotal role of ZLD in safeguarding Bangladesh’s environmental future, the government has stepped up its support for the textile industry’s transition. From financial incentives and public-private partnerships to capacity-building initiatives and regulatory reforms, a comprehensive framework is taking shape to accelerate ZLD adoption.

Fostering Innovation and Research

Bangladesh’s academic institutions and research centers are also playing a crucial role in driving water technology forward. Collaborations between industry and academia are flourishing, fostering the development of innovative solutions tailored to the nation’s unique challenges.

A Sustainable Future Beckons

As 2024 unfolds, Bangladesh’s textile industry stands at a crossroads, poised to embrace a future where zero liquid discharge is the norm rather than the exception. With unwavering determination and a shared vision for a greener tomorrow, this vibrant sector is poised to lead the way in sustainable manufacturing, setting an example for the rest of the world to follow.

From the bustling factories of Dhaka to the rural communities dotting the country’s lush landscapes, the ripples of this transformation will be felt far and wide. A cleaner environment, healthier communities, and a thriving textile industry – this is the promise of ZLD, and Bangladesh is determined to make it a reality.

Pricing for Zero Liquid Discharge (ZLD) Systems in Bangladesh (2024)

As Bangladesh’s textile sector accelerates its transition towards Zero Liquid Discharge (ZLD) for sustainable wastewater management, the costs associated with implementing these advanced systems have become a critical consideration. While the long-term benefits of ZLD are undeniable, the upfront investment required can be substantial, particularly for small and medium-sized enterprises (SMEs).

In 2024, the average cost for a comprehensive ZLD system in Bangladesh’s textile industry is estimated to range between BDT 50 million to BDT 200 million (approximately $500,000 to $2 million USD), depending on the scale of operation and the specific technologies employed.

Here’s a breakdown of the typical cost components:

- Pre-treatment Systems: BDT 5 million – BDT 20 million

- This includes processes like screening, equalization, neutralization, and primary clarification.

- Membrane Filtration Units: BDT 15 million – BDT 60 million

- Reverse osmosis (RO) and nanofiltration (NF) systems for water recovery and concentration of waste streams.

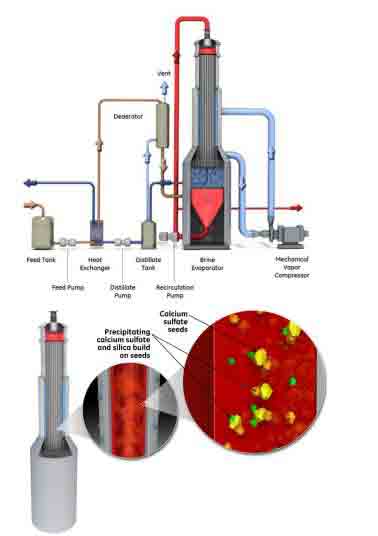

- Evaporation and Crystallization Systems: BDT 20 million – BDT 80 million

- Thermal evaporators, forced circulating evaporators, and crystallizers for zero liquid discharge.

- Sludge Management and Disposal: BDT 5 million – BDT 15 million

- Processes for handling and disposing of concentrated solid waste from the ZLD system.

- Ancillary Equipment and Installation: BDT 5 million – BDT 25 million

- Pumps, piping, instrumentation, electrical systems, and installation costs.

It’s important to note that these prices are approximate and can vary significantly based on factors such as the specific wastewater characteristics, the desired level of treatment, and the choice of technology providers.

To offset the high capital costs, the government of Bangladesh has introduced various financial incentives and subsidies for textile factories investing in ZLD systems. Additionally, many manufacturers are exploring cost-sharing models and public-private partnerships to make ZLD adoption more feasible, especially for SMEs.